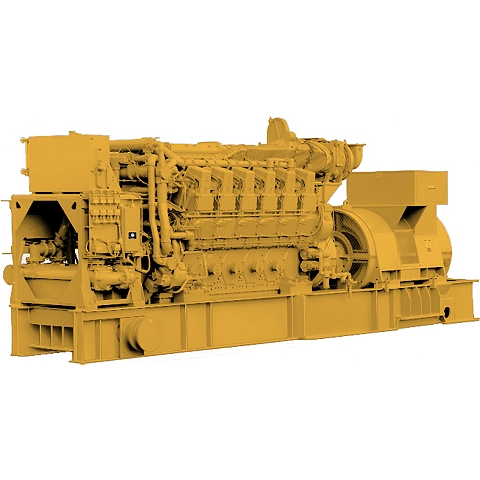

Product Description

Producing reliable power from 4400 to 4850 kVA at 50 Hz, our 3612 diesel generator sets are made to meet your mission critical, continuous, standby and prime applications. We’ve designed each to ISO 8528-5 transient response requirements and to accept 100% rated load in one step. The generator set is certified for low fuel consumption.

Generator Set Specifications

- Maximum Rating

- 4850 kVA

- Minimum Rating

- 4400 kVA

- Emissions/Fuel Strategy

- Low Fuel Consumption

- Frequency

- 50 Hz

- Speed

- 750 & 1000 rpm

- Duty Cycle

- Prime, Continuous

Engine Specifications

- Engine Model

- 3612 V-12,4-Stroke Water-Cooled Diesel

- Bore

- 11in

- Stroke

- 11.8in

- Displacement

- 13524in³

- Compression Ratio

- 13:01

- Aspiration

- TA

- Fuel System

- Direct unit injection

- Governor Type

- Generator Set Monitoring System (GMS)

Generator Set Dimensions

- Length - Maximum

- 404in

- Width - Maximum

- 99.62in

- Height - Maximum

- 156.6in

- Dry Weight - Genset (maximum)

- 112690lb

Standard Equipment

-

- Air Inlet System

-

- Air cleaner

- Turbocharger, watercooled, engine oil lubricated

- Breather, crankcase, top-mounted

- Aftercooler, fresh water, corrosion resistant coated (air side)

- Air inlet shutoff

-

- Cooling System

-

- Water temperature regulator

- Engine coolant water drains

- Jacket water thermostats

- Front mounted turbos

- Three-bundle oil cooler

-

- Exhaust System

-

- Dry, gas tight, exhaust manifold

- 457 mm (18 in) Cat bolt pattern

- Includes adapter, flexible exhaust fitting

-

- Fuel System

-

- Simplex or duplex

-

- Generator System

-

- Custom generator per generator data sheet completed by dealer

-

- Governor System

-

- UG Actuator

-

- Lube System

-

- Centrifugal oil filters with single shutoff

- Oil filler and dipstick

- Crankcase explosion relief valves

- Oil pressure regulating valve

- Wet oil sump. Includes engine-driven main lubrication and oil pumps, oil lines and oil pan

- Service side engine mounted on cylinder block inspection covers

-

- Mounting System

-

- Damper, torsional vibration

- Engine and generator mounting

-

- Starting / Charging System

-

- Line group for single point custom connection

- Vane type air starter

- Two motors, engine mounted at rear, on left side

- Air silencer

-

- General:

-

- Paint, Caterpillar yellow

- Gear driven pumps: Fuel/oil/jacket water/Aftercooler/Oil cooler water

Optional Equipment

-

- Air Inlet System

-

- Vertical support bracket

- Soot filter

- Boost control valve

- Heavy duty air cleaner

- Air cleaner louver assembly

- Air inlet adapter

-

- Cooling System

-

- Heating aids

- Auxiliary water pump

- Expansion tank

- Heat exchanger for single circuit

- Cooling system aids

-

- Exhaust System

-

- Flexible exhaust fittings

- Weld flange and related hardware

-

- Fuel System

-

- Duplex primary fuel strainer

- Fuel system connections

- Fuel priming pump

-

- Generator System

-

- Anti-condensation space heaters

- Class F insulation

- Busbar connections

- Winding temperature detectors

- 3 Phase, six Leads, WYE

-

- Governor System

-

- 230 UA

- EGB actuator

- Digital programmers

- Electronic/actuators

- 723 Plus

- Battery backup/power supply

-

- Lube System

-

- Oil pan drain valve

- Lube ANSI adapter (Emergency connection)

-

- Mounting System

-

- Spring type vibration isolators

- Vertically restrained

- Isolator

- Non-vertically restrained

-

- Starting / Charging System

-

- Compressed air flex hose

- Redundant air starters

- Pressure reducing valve

- Turbine type air starters

-

- General:

-

- Custom paint colors