Creating set loading, transportation, and unloading standards and practices is essential when handling large machinery and keeping people safe. Find guidelines below for the proper loading and unloading of heavy equipment to help you safely haul construction and heavy machinery.

Preparing Construction Equipment for Transport

Preparation is key. Construction injuries can occur when loading and unloading equipment, so it’s essential to prepare and take safety measures from the start to mitigate liabilities and avoid construction accidents. Let’s review the proper ways to prepare heavy equipment for transport.

1. Perform a Documented Risk Assessment

Regarding heavy equipment liability, construction companies are responsible for dotting their i’s and crossing their t’s. Risk assessments are preemptive compliance documents allowing you to prove how detailed and thorough your fleet management processes are.

Consider adding one for your equipment transportation preparation protocol. They can be done by a senior manager or supervisor, containing the total operation and transportation timeline and its weight loads, plus relevant project risks and what’s been done to address them.

2. Outfit Sites With PPE

We can’t say it enough — safety is the backbone of the industry. Having your crew wear a complete set of personal protective equipment is a safety standard across all construction operations, not just when preparing for the safe and legal transport of heavy cargo. It’s also something routinely overlooked, with many sites taking shortcuts to chain up a trailer quickly and move on to the next task.

PPE documentation is also a risk-mitigation strategy. You’ll round out a stronger risk assessment and permit application when you note all the safety protocols you and your crew adhere to on top of routine tie-down requirements for heavy equipment.

3. Inspect the Hauling Capacities of Your Truck or Trailer

Next in line when preparing for heavy equipment transport is to check the things that’ll be doing the actual transporting. A complete inspection of your trailer or truck includes the following:

- Tires: Assess the condition of your trailer and truck tires, notably for tire pressure. Multi-ton machines take a toll on tire air pressure and will quickly deflate any that are already weak.

- Lights: Front and brake lights should work without a hitch.

- Brakes: Similar to tires, your oversized load affects your vehicle’s braking abilities. Assure all brake functions and components are in good shape.

- Tie-Down Points: Check your load’s required point number, securement condition, and spacing. Most states’ standards mandate a minimum of four tie-down points for loads exceeding 10,000 lbs, each with its own binder or boomer and individual chains connected to trailer hitch points. These boomers are responsible for supplying the tension to tighten the actual chain connection and, as such, should be inspected themselves.

- Weight: Confirm your tie-down working load limits add up to at least half of the total weight of your load.

While most states mandate four tie-down points, and most operations concede to that number, some heavy equipment requires even more. Any machine with attachments or appendages must have those attachments dislodged and separately secured, meaning now a minimum of five tie-down points. A typical example of this is when securely transporting excavators.

How to Load Heavy Equipment Safely

A load is only as strong as its weakest link. Weak links often happen because the process was rushed or done halfheartedly, not because the procedure wasn’t followed.

Loading heavy equipment safely is not just about driving a new dozer up the ramp, looping in a few chains, and sending it on its way. We’ve got a few more points of consideration to ensure you reliably and legally transport heavy cargo. Refer to these safety measures for secure loading operations.

1. Designate Responsibilities

Before actual loading occurs, the team should have a clear understanding of who’s in charge of what. You’ll need someone to drive the equipment onto the deck, but you’ll also need a spotter to deliver hand signals and direct the driver up the ramp and onto the trailer bed. Likely, they won’t have a clear line of site to do so themselves.

Moreover, the rest of the crew should be notified if a loading procedure is on the docket. No drifting personnel or other vehicles should interrupt loading operations, which are generally unsafe to stop once they have started.

2. Clean the Ramp and Trailer

Ramps and trailer decks should be as dirt-, oil-, and debris-free as possible, especially if they are metal. This ensures the piece of loading equipment has as much traction as possible to move up its ramp. A clean ramp and trailer bed are also dry, and clear of ice, snow, and water. If you are still concerned about equipment smoothly moving up ramps, consider employing ramp friction devices during this step.

3. Clear and Level the Loading Area

Pick an uninhabited and even space to set up the ramp and perform heavy equipment loading. Again, this is intuitive, but amid a busy workday or at peak hours in the yard, such measures can fall by the wayside.

You’ll also want to ensure the actual ground in the loading area is compact enough to bear the total weight of your loaded trailer. After rain or during seasons with thaw, the combined weight of these two vehicles can cause sinkage.

4. Begin the Machine/Ramp Line-Up

Slow and steady is the name of the game here. With the driver in the cab and a spotter positioned in plain view, begin driving the heavy equipment up the cleared ramp and onto the transportation vehicle’s deck.

Note that the machine’s center of gravity will shift during this ramp movement. This is the most dangerous part of the loading process, with the equipment’s weight caught momentarily in a point of limbo. Just keep moving gradually.

Also note that when appropriately positioned at final rest on deck, most of the equipment’s weight should be distributed toward the front of the trailer. This avoids fishtailing while en route.

5. Start Chaining Down Heavy Equipment

Check state laws on securing heavy equipment during public highway transportation. While the 4-5 tie-down points are near-universal, each state has additional oversized cargo restrictions and regulations to respect.

With the heavy equipment safely positioned on the deck, you can initiate one of the most critical steps in the loading and unloading procedure — tying it down.

There are three predominant concerns with chaining down:

- Tight, secure chains: Your chain should have no room for movement. Equipment shouldn’t be able to bounce or shift during transport.

- Properly located tie-down points: Most manufacturers will create labels for the tie-down points to make them easier to follow. Be especially careful if these are by a machine’s hydraulic hoses, cylinders, or brake components, though. Tying down heavy equipment at appropriate points prevents equipment damage and ensures the tightest, most compliant links.

- Adequately matched chain and hook binder grades: If you look closely at every 4-5 chain links, you’ll find a number etched into the metal. Cross-reference that number with the one printed on the boomer handle, ensuring they’re aligned. The sum of the working load limits of all your tie-down components must equal at least 50 percent of the weight of the cargo. Always ensure the chain’s grade and working load limit don’t exceed the boomers’ listed limit.

Here are a few additional reminders to achieve the proper way to chain down an excavator, loader, and more:

- All chains fastened linearly, with downward force, with no horizontal twists, bends, or angles

- No slack. Wrap the excess chain around the rest of the link so it won’t come loose.

- At least four chains in use. Use two connecting to the trailer’s front corners and two to the trailer’s back corners. The tension from these opposing forces should keep the equipment in place.

- Always review chain and hook sizes. You need to guarantee they’re complementary and tight, not mismatched.

How to Transport Heavy Equipment Safely

Vehicle accidents due to heavy trucks and cargo transport cause injuries and fatalities every year. This merely reinforces how vital it is to follow proper loading and unloading procedures in the yard and safely haul that equipment while on the road. We’ve got a few strategies.

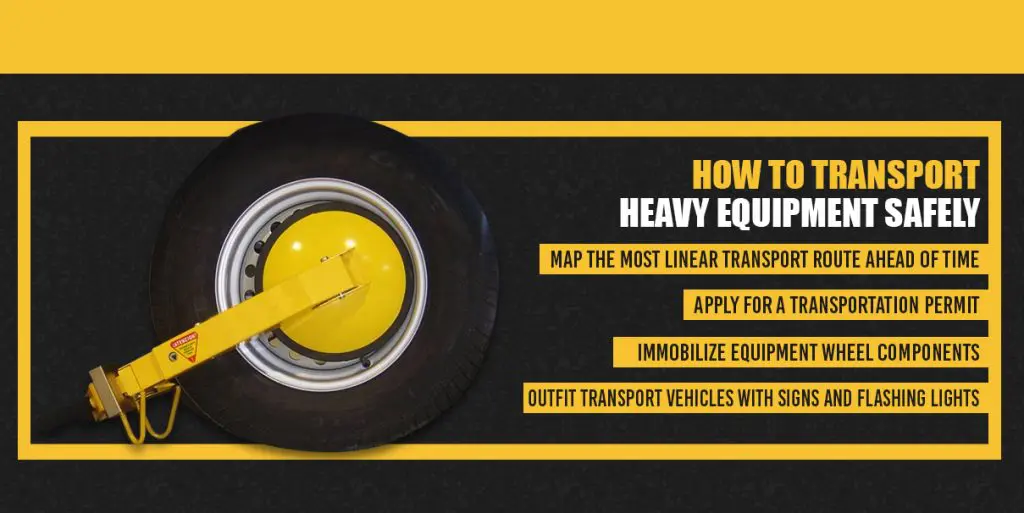

1. Map the Best Route

Mapping your route before transporting your heavy equipment helps avoid accidents, such as trying to pass under an overpass that’s too short for your transport vehicle. You can also perform a run-through of your route to ensure there are no obstacles.

Look at the width of the road and bridge analysis to create the safest transportation route for your heavy equipment. The fewer turns, starts, stops, bridges, or challenging terrain can make the trip go smoothly and keep your drive, equipment, and passersby safe.

2. Apply for a Transportation Permit

This is especially important if your load qualifies as oversized or overwidth, which — let’s face it — most heavy construction equipment will. Cranes, excavators, dump trucks, graders, dozers, and scrapers are just a few that carry extra heavy equipment liability. Prepare accordingly, whether that means deconstructed transport strategies that avoid overwidth or overweight designations or applying for the proper state permit from the onset.

3. Immobilize Equipment Wheel Components

It takes a little extra time, but the security is worth it. Apply the equipment’s parking brake. Also consider using wedges, chocks, or cradles against equipment wheels, securing them in place and preventing them from rolling on deck. They will also bolster your defenses against the following weight-distribution forces that naturally occur during transport:

- Forward force: 80 percent of vehicle weight gets applied when braking during transport

- Rearward force: 50 percent of vehicle weight gets applied when accelerating, shifting gears, or reversing

- Upward force: Up to 20 percent gets applied when driving uphill or over bumpy terrain

- Sideways force: 50 percent gets applied when turning, lane changing, or braking while turning

This is also a great time to double-check any extra machine-specific loading and transportation conditions outlined by a spec sheet or manufacturer’s guidelines.

4. Outfit Transport Vehicles With Safety Signs, Labels, and Lights

If you’ve ever seen an oversized load on the highway, you’ve likely noticed they’re marked with large banners, signs, and plenty of lights. These safety additions help others on the road know to use caution when approaching and passing. Transporting oversized loads can require one or multiple escort vehicles that alert other drivers to keep themselves and the driver safe.

If transport trucks are working alongside escort vehicles, they communicate through CB or two-way radios to ensure prompt, safe communication. Outfitting your transport equipment with the proper signage, labels, and lights helps you safely haul equipment to and from your site.

5. Run and Document Inspections While En Route

Heavy cargo’s safe and legal transport doesn’t stop once you start the ignition. While your heavy equipment is on the way to your site, perform regular inspections and check-ins, especially if you’re transporting your heavy equipment across great distances.

Industry standards designate when you should perform check-ins or inspections while your heavy equipment is on its way to its destination:

- Stopping for check-in during the first 50 miles of travel.

- Stopping every three hours or 150 miles, depending on what comes first.

- Having the new driver run and document a full inspection at every change of driver or duty station.

How to Safely Unload Heavy Equipment

Safely unloading construction equipment rounds out the compliant transportation process. As with other protocols, there are key steps and risk-mitigation strategies to ensure the success of this final step.

1. Clear and Level the Unloading Site

Before your transportation vehicle arrives and you unload your equipment, inspect your designated unloading area to ensure it’s clear and ready for unloading. Uneven loading grounds and slick ramps can make unloading more challenging than expected, causing unexpected downtime or problems.

Do more than just clear any obstacles, debris, or dirt. Your personnel should also be aware of cargo schedules so only your relevant crew members are present when your heavy equipment arrives, making the process go more smoothly.

2. Do a Walkthrough

Once your transport vehicle arrives, guide it to the correct unloading site. Have the unloading ramp ready for deployment once the transport vehicle arrives, but you should conduct an additional visual inspection to ensure it’s clean and ready to go.

Once you’ve confirmed your ramp is ready for unloading, line up the ramp with the back of the trailer bed with as much accuracy as possible since you won’t have time to reposition once the machinery starts backing up.

Once you have everything in place, conduct a final walkthrough to better understand your equipment’s condition. Check the hitches and tires. You can also review roles and tasks with personnel, appointing an equipment operator and spotter before breaking down chain tie points.

Look at the condition of the tie points before you move forward with the unloading — a shifted load can create a hazard. If you’ve found that the load has shifted, hold off on undoing any chains or straps until you create a customized unloading plan.

3. Free the Load

After your walkthrough and determining that everything is in good order, slowly release tie-bounds and chains. Begin this process one at a time, starting in the rear corners. If any chains are wrapped around the links, unravel them and loosen them with their wrench boomers.

Use caution when starting this process since any chains can still be tight or pressurized. Moving too quickly can cause a metal chain to suddenly snap up if the tension isn’t reduced correctly.

4. Slowly Back the Heavy Equipment Down the Ramp

As you unload equipment, remember to take it slowly and to keep a safe distance between the spotter and the machinery. During the unloading process, your operator’s visibility can decrease until the equipment is fully unloaded, so ensure your spotter is positioned in a highly-visible but safe area. The rest of your personnel should stay away from the unloading site until your machinery has finished unloading since all attention should be on removing the equipment from the transport truck.

5. Wrap It Up

Do a final ground inspection of all equipment, the transport vehicle, anchor points, and tools before sending everyone on their way. Document the conclusion of the transport — and pat yourself on the back for successfully completing the safe and legal transport of heavy cargo.

Contact Thompson Tractor for Heavy Equipment in Alabama

Transporting construction equipment is no easy undertaking. We hope this resource has provided insight into its proper techniques and protocol for your heavy load securement and transportation operations.

Share it online or print it off for future reference, and reach out to Thompson Tractor with any construction equipment questions or concerns.