Owning and operating heavy equipment is a significant investment. Even small companies can invest hundreds of thousands of dollars in their machinery. If you own or operate heavy equipment, you’ll want to take the necessary steps to maintain it to extend its life span and keep it operational on the job.

Importance of Equipment Maintenance

Many companies and machinery owners participate in two types of equipment maintenance:

- Routine maintenance: This type of maintenance operates on a fixed schedule, which includes regular maintenance tasks, such as changing filters and oil, checking fluid levels, and testing various pressures. You can find the procedures for routine maintenance in your machinery manual.

- Preventative maintenance: This type of maintenance is broader than routine maintenance. Preventative maintenance looks to stop potential problems before they occur, saving time and money.

Both routine and preventative maintenance are essential for your equipment’s health and life span. Some of the main benefits of conducting maintenance include:

- Increased longevity: Regular maintenance on your machinery can help extend its life span. Properly maintained equipment lasts longer than items that aren’t properly cared for. Preventing problems ensures your machinery will be available when you need it.

- Greater availability: Equipment that breaks down will be unavailable to operators, which can result in costly repairs and unprofitable downtime. Preventative and routine maintenance ensure your machinery remains operable.

- Lower costs: Equipment that suddenly breaks down can create unexpected expenses, requiring extensive repairs or replacements. Poorly maintained equipment is more likely to experience compound failures that lead to costly repairs. Preventative and routine maintenance can help reduce compound problems and reduce overall expenses.

- Boosted confidence: It’s essential for machine operators to feel confident in the performance of their equipment. Operators are less likely to feel secure when using poorly maintained equipment, which could affect their productivity. Confident workers can help watch for potential issues and report them before they become expensive.

- Reduced chance of litigation: Failing to perform maintenance on your equipment is an accident waiting to happen, which could result in lawsuits requiring you to pay damages. You can prevent litigation if you practice due diligence, regularly maintain your heavy equipment, and keep accurate records.

- Improved safety: Safety should be a priority in any workplace, especially when working with heavy machinery. Well-maintained machinery is safer to operate than equipment. Failing to perform regular maintenance can cause equipment failure that could cause serious injury to operators or those nearby. You can sustain the safety of your workers by performing routine and preventative maintenance.

Equipment Maintenance Procedure

If you’re wondering how to maintain heavy equipment, it’s essential to follow specific steps and procedures to create an effective program. You can create a program within your company to extend your equipment’s life span and ensure your operators’ safety. Follow the steps below to create an effective and successful maintenance program:

- Establish what the program covers: The first step in a successful program is listing what the program covers, such as the required maintenance for each machine. A maintenance program should also work quickly to make adjustments or replace outdated or worn-down parts to correct any potential issues.

- Identify who’s responsible for administering the program: Your company’s size and capacity will determine who you can make responsible for administering your maintenance program. A large company with fleets of heavy equipment may have a senior service technician or head mechanic. A small company may have the owner or a foreperson run the program. Regardless of the size of your company, it’s essential to clearly define who’s in charge and responsible for the maintenance program.

- Make a schedule for service milestones: Consistent scheduling is essential for performing maintenance on your heavy equipment. Each machine will have a unique maintenance schedule. You can follow the manufacturer’s recommendations, respond to seasonal requirements, or perform maintenance based on the practical needs of each machine. Quality maintenance schedules also allow technicians to prepare for preventative maintenance and plan for routine services.

- Document your service and preventative maintenance: Prioritize documenting your routine and preventive maintenance in your maintenance program, giving you a clear image of your equipment’s history. You can also keep track of your maintenance schedule and services so you know what was performed and when you can expect to perform your maintenance next. Well-kept records can also identify potential problems in similar equipment and support the value of your machinery at resale.

While you can perform maintenance independently, it’s best to use professional services. Professionals have the experience and expertise to maintain your equipment and keep it available and operational for a long time. Skilled technicians can easily identify problem areas and quickly perform maintenance to keep your equipment in good shape, reducing downtime and costs while improving worker safety.

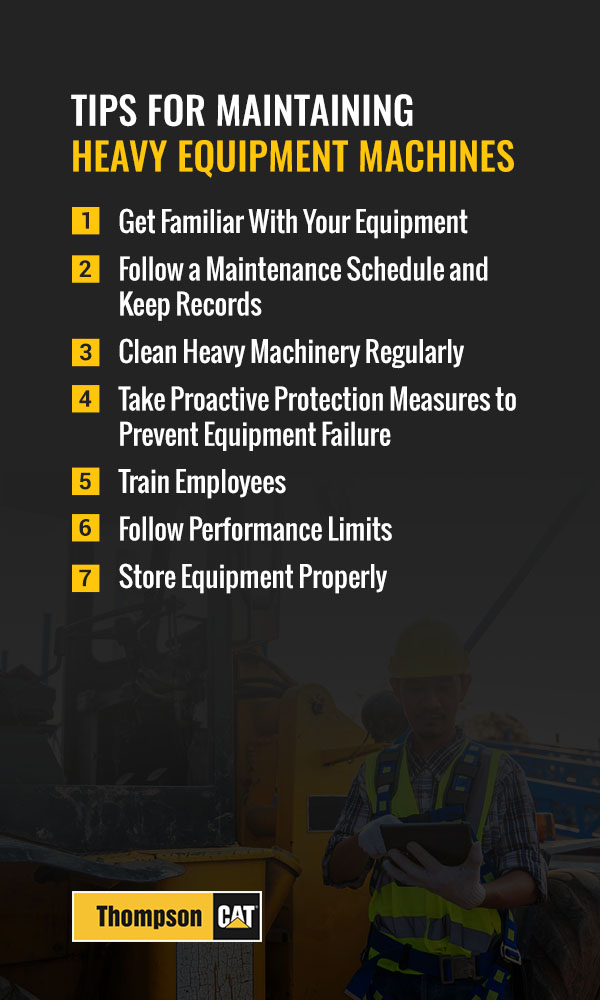

Tips for Maintaining Heavy Equipment Machines

Maintaining your equipment can help extend the life of your machinery and keep it in peak operating condition for as long as possible. Below are some maintenance tips for heavy equipment to help you learn how to extend the life of heavy equipment.

1. Get Familiar With Your Equipment

First, familiarize yourself with your heavy equipment. You should read the manufacturer’s manuals to understand the machine’s parts, functions and maintenance tips. The manual should also include instructions for fixing common problems or malfunctions.

You should also check in regularly with your heavy equipment operators. These individuals have the most experience with your heavy equipment and have a feel for how it operates. They may notice if something is wrong before your machine’s monitoring equipment can.

2. Follow a Maintenance Schedule and Keep Records

Your heavy equipment machine’s manual will have an equipment maintenance procedure and schedule you should follow. However, remember that the recommended maintenance periods are when machinery operates in typical conditions. There may be some instances where you need to perform maintenance more regularly, such as when working in extreme temperatures, ice, mud or snow.

You’ll also want to follow a heavy equipment maintenance checklist to ensure you’re not overlooking any part of your machinery. Some things you should include on your list to perform maintenance on include:

- Undercarriage inspections for damage, rust or dents

- Break inspections, including checking fluid levels, fittings, lines and filters

- Checking battery connections, air filters, fluid levels, hoses and belts

You’ll also want to keep records of your performed maintenance to track what you need to do and identify potential maintenance areas for other types of machinery.

3. Clean Heavy Machinery Regularly

Keeping your equipment clean can reduce the risk of damage and extend the life of your machinery. Various natural substances your machinery can be exposed to can damage electrical components, such as dirt, mud and dust. These substances can also contribute to rusting, speeding up general wear and tear of your equipment over time.

Ideally, you’ll want to set a regular cleaning schedule to ensure your machinery stays in good shape. You can select a schedule to pressure wash your machine to remove the buildup of different substances and to clean your engine or filters.

4. Take Proactive Protection Measures to Prevent Equipment Failure

Sometimes, accidents occur, or you experience unavoidable equipment failure. However, there are a few types of equipment failures that you can prevent by taking preventive measures to protect your machinery:

- Erratic failure: Overloads, hardware or software malfunctions commonly cause erratic failures. While this type of machine failure can be more challenging to prevent, utilizing diagnostic equipment, such as scanners or emissions analyzers, can significantly reduce the risk.

- Mechanically-induced failure: Mechanical malfunctions cause failures that are easy to avoid. You can prevent this failure by maintaining your machinery’s alignment and lubrication, tightening your fasteners, and replacing broken parts.

- Thermally-induced failure: This failure can occur during extreme temperature fluctuations or conditions. You can prevent thermally-induced failure by storing your machinery in shaded areas during hot summer days or on raised surfaces in the winter.

5. Train Employees

It’s essential to train your employees to reduce the risk of equipment failure and unnecessary wear and tear. Trained employees will know how to work machinery in pre-set operating limits. You’ll also meet local, state, or federal laws that require employee training before using specific heavy equipment.

Employees should know how the equipment they’re using works, what precautions they should take, and what to do in an emergency. You should update employees’ knowledge with additional training to ensure their skills are up to date and they have the necessary information to work with updated software or hardware.

6. Follow Performance Limits

Your manufacturer’s manual will help you understand the limits of your machinery, such as load limits and recommended usage. Going beyond the limits of your machinery can leave you vulnerable to failures or overheated, creating wear and tear. Only operate your heavy equipment according to the manufacturer’s limits to prevent unnecessary damage.

7. Store Equipment Properly

Storing your equipment correctly can help reduce unnecessary damage to your machinery. Always keep your equipment in a dry, covered area and away from harsh sunlight and water to prevent rusting. If you’re not using your machinery often and leave it in storage for long periods, you should start and move your equipment at least once a month to help maintain lubrication and prevent damage.

How Thompson Tractor Can Help You Maintain Your Heavy Equipment

Maintaining your heavy equipment takes time, money and labor, which can slow some of your operations and make it challenging to stay on track. However, it’s essential to regularly service your equipment. Rather than handling the maintenance process yourself, consider choosing Thompson Tractor to help you maintain your essential equipment.

We can perform regular inspections and maintenance on your heavy construction equipment so you don’t have to, helping you save time and money. Some of the main benefits of outsourcing your equipment maintenance to us include:

- Reduced costs: Rather than risking unnecessary downtime by waiting on a maintenance worker or having to spend money on buying maintenance tools, outsourcing your maintenance to us can help you save on costs. We have a team dedicated to equipment maintenance and can help you perform regular upkeep on your equipment.

- Reduced downtime: Equipment failure can result in unwanted downtime, which can cost you in the long run. Trusting us to complete your equipment maintenance ensures your maintenance is performed by professionals, giving you peace of mind your equipment won’t fail again. Our expert team can perform maintenance quickly and effectively, helping to reduce your overall downtime and allowing you to return to your operations.

- Expert maintenance services: When you trust us with your maintenance, you can rest easy knowing that a team of experts will perform your maintenance. We can perform your repairs and maintenance quickly and effectively, helping you get back on track sooner.

- Access to proper maintenance tools: Advancements are constantly being made when it comes to heavy equipment. If you perform in-house maintenance, your team will need to keep up with industry changes while upgrading their tools at the same time. When you choose us for your maintenance, you can rest assured that we have the necessary tools to perform high-quality maintenance and keep your machinery at peak performance.

- Access to emergency maintenance: Even after taking all the precautions, equipment still has the potential to fail. Rather than scrambling to find someone to repair your equipment during a failure, you can trust that we’ll repair your equipment as quickly as possible, helping you get back to business faster.

- Frees up time to focus on your business: Without having to worry about how you’re going to maintain your heavy equipment, you have more time to focus on your business. You can provide better service to your clients with the extra time you have, and you can rest assured that your heavy equipment maintenance is done right the first time.

Choose Us to Service Your Heavy Equipment

Regular maintenance on your heavy equipment is essential for your team’s safety and your business’s success. However, performing routine maintenance on your own can be costly and waste your valuable time. Let us take on that work for you with our heavy equipment maintenance services.

We can handle the maintenance requirements for your heavy machinery and provide flexible terms, allowing you to get the right equipment for your job and return it once you’re done. Without the responsibility of caring for heavy equipment, you can use your resources in the way that best suits your business.

Contact us today to learn more about how we can help.