IROCK Screens

-

TS-409 – Mobile Scalping Screen

-

The IROCK TS-409 delivers versatility and provides a heavy duty configuration while still allowing for easy and economical transport.

- High Energy 4’ x 9’ screenbox delivers the most aggressive screening action in its class.

- Discharging oversize material at 11’ 1” (3.38m), the 42” (1050mm) wide 3-ply belt allows for efficient stockpiling.

- Direct feed 5.5 yd3 lined hopper equipped with a 48” heavy duty 4 ply belt for heavy duty applications.

-

TS-4512 – Mobile Scalping Screen

-

The IROCK TS-4512 Track Scalping Screen provides the best solution for operators who don’t require the capacity of the larger screener models. The TS-4512 has all the class leading features of the TS-Series, such as high quality components, durability and reliability.

- High Energy 4.5’ x 12’ (1.37m x 3.66m ) Screenbox with 1/3″ (10mm) throw provides the most aggressive screening action in its class.

- Discharging oversize material at 11’-4” (3.45m), the 48” (1200mm) wide 3 ply belt allows for efficient stockpiling.

- 7.8 yd3 (6 m3) hopper equipped with a 48” (1200mm) heavy duty 4 ply belt designed for heavy duty applications.

-

TS-516 – Mobile Scalping Screen

-

The TS-516 track scalping screening plant is ideal for heavy-duty applications that require screening of materials such as recycled concrete, iron ore and aggregates. The unit can also be used in crusher circuits. This mobile, robust and versatile machine handles sticky clay, topsoil and can process up to 570 TPH.

-

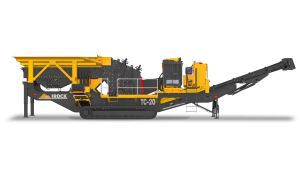

TS-620 – Mobile Scalping Screen

-

IROCK’s largest screening plant, the TS-620 mobile scalping screen, is known for its high output in heavy-duty scalping applications. The TS-620 tracked unit features a robust overall design and can process up to 900 TPH.

- An 11.7-cubic-yard hopper features the highest capacity available in this class of screeners.

- Optional top deck bofar bars, top deck punch plate, heavy-duty top finger deck, and bottom finger deck prolong screen and crusher life in rugged applications. An optional apron feeder can be substituted for the belt feeder.

- The two-deck design offers 234 square feet of screening area and the ability to sort up to three different product sizes.

- Stacking conveyors feature discharge heights up to 16-feet, allowing for the production of more material before having to move the finished product. A 63-inch-wide discharge conveyor, the widest in the industry, reduces material build-up at the screen’s discharge point. It also features an impact bed, which extends the life of the conveyor.

Contact Thompson Tractor for all of your Screen needs

Request a Quote

The IROCK TS-409 delivers versatility and provides a heavy duty configuration while still allowing for easy and economical transport.

The IROCK TS-409 delivers versatility and provides a heavy duty configuration while still allowing for easy and economical transport.