Understanding Cat® Preventive Maintenance Services

Heavy equipment preventive maintenance is essential for keeping costs low and minimizing unplanned downtime, especially for companies with large fleets.

Although it’s a similar concept to routine maintenance, preventive maintenance is slightly broader. Rather than performing basic upkeep procedures like filter and oil changes, preventive maintenance aims to catch issues before they can impact your operations.

The Importance of Heavy Equipment Preventive Maintenance

So why is it important to subscribe to a preventive maintenance program rather than stick to basic routine maintenance?

The biggest benefits of following a preventive maintenance program include:

- Equipment availability: Preventive maintenance can help you address serious equipment issues before they lead to breakdowns, which reduces unplanned downtime and maximizes fleet availability.

- Operator safety: Following a preventive maintenance program is essential for keeping your crew safe from dangerous breakdowns and other equipment malfunctions.

- Longer lifespan: Addressing equipment issues early can help you maintain high performance for longer periods of time, which minimizes your need to purchase new machinery.

- Reduced costs: Regular maintenance helps you identify problems early on, reducing your risk of costly malfunctions and extensive downtime. Preventive maintenance can also help you avoid costly litigation resulting from equipment-related accidents, which protects your reputation and helps improve your company’s chances of winning bids.

- Peace of mind: When you have a reliable preventive maintenance team on your side, you and your operators can rest easy with the knowledge that your equipment can perform at its best.

Cat Preventive Maintenance Services

Preventative maintenance programs can help reduce downtime and improve the uptime on your equipment fleet. A Thompson Certified Technician performs these services in our shop or at your convenience at your jobsite. Whether you have a large fleet or a single machine, Thompson Tractor Company takes pride in helping you protect your investments.

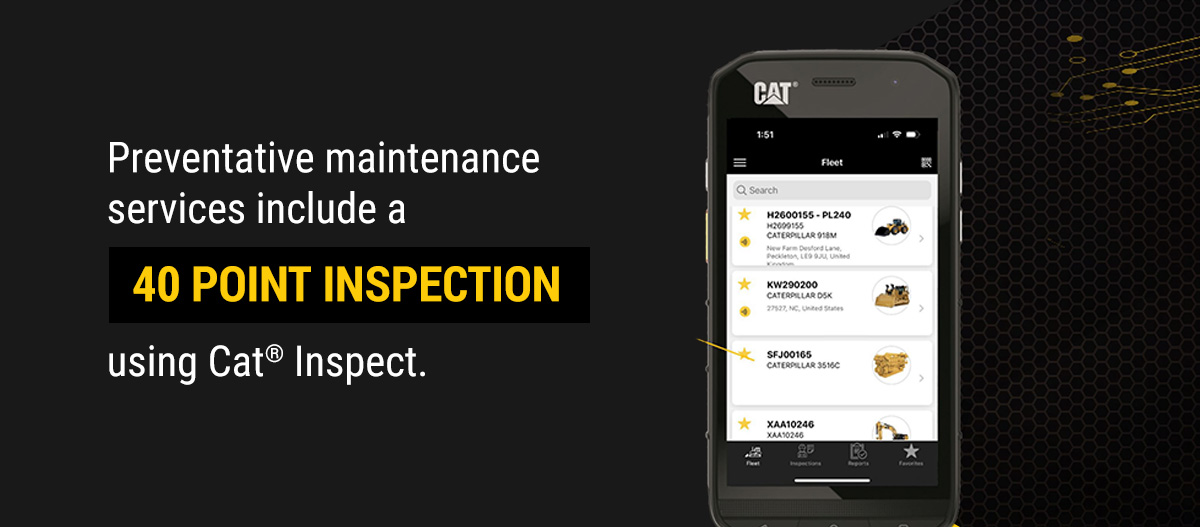

You can choose from a one-time service or a customized bundle based on your needs. Preventative maintenance services include a 40 point inspection using Cat® Inspect. You will also receive a custom report that will help you optimize the life of your equipment.

Essential Components of Cat Preventive Maintenance Programs

Each fleet requires different maintenance considerations at different intervals, which is why hiring a professional service provider can help you design a solution tailored to your company’s needs.

At Thompson Tractor, we follow Cat preventive maintenance protocols. Our preventive maintenance services include the following steps:

- Maintenance scheduling: Keeping to regular maintenance intervals helps ensure you catch issues before they have a chance to escalate into something more serious.

- Oil analysis: A professional fluid analysis can reveal issues you may not be able to identify in a visual or mechanical inspection.

- Filter replacement: Regularly replacing your equipment filters improves airflow and reduces your risk of future breakdowns.

- Seasonal preparations: Getting construction equipment ready for the summer and winter seasons is essential for minimizing environmental strain.

The Comprehensive Equipment Inspection Process

Heavy equipment typically experiences intense vibration, high friction, and extreme temperatures — all of which contribute to accelerated wear and tear unless managed properly.

Frequent inspections are critical pieces in a preventive maintenance program because these times are when you will uncover important equipment issues. The different types of inspections you might perform as part of your preventive maintenance routine include:

- Pre-trip: A quick 30-minute visual inspection at the beginning of each shift can help you and your operators catch equipment issues that could impact the day’s work, preventing serious emergencies from happening later.

- Periodic: In addition to the typical daily and weekly routine inspections, conducting more thorough inspections once every month or quarter enables you to identify hidden damage you may have missed during a typical inspection.

- Post-repair: Inspecting equipment shortly after it undergoes repairs helps verify that the problem has been fixed and that the machinery is once again operating at peak capacity.

Recent construction technology advancements can also simplify your usual inspection processes by tracking equipment condition in real time. All you have to do is check your fleet management system to see which machines may be experiencing issues.

Why Choose Thompson Tractor for Your Preventive Maintenance Needs?

If you manage a large fleet or you just want to ensure your equipment is in the best possible condition, call on the professionals at Thompson Tractor. We offer preventive maintenance services to help you minimize downtime and reduce repair costs.

With more than 500,000 square feet of service bays and a full team of experienced technicians behind us, you can count on us to help you keep operations moving.

For more information, contact your local customer service rep or fill out the following form. We’ll help you find the answers you need.