Skid Steer Bucket Guide

Skid steer loaders are versatile compact equipment that support earth-moving and material-handling tasks. They pair with different attachments, including a range of buckets — a key feature that makes them adaptable for various projects. Skid steers can handle small- or large-scale construction, agriculture, infrastructure, and industrial applications.

Using the right skid steer bucket for various tasks improves your business’s operational efficiency and productivity. For this reason, finding the proper bucket for the job is crucial. Consider factors like equipment compatibility, size, weight capacity, and bucket type.

To learn which type of bucket attachment suits your needs, read our detailed skid steer bucket guide below.

Understanding Skid Steer Buckets

Skid steer buckets offer the advantage of interchangeable attachments, allowing operators to switch between different bucket types based on specific tasks. These attachments are highly adaptable, whether they’re made of a lowered profile for improved visibility, toothed for powerful digging, or smooth-edged for precise grading.

Because skid steers are compact, they can dig and haul materials across different projects without needing larger, heavier pieces of equipment. Using the appropriate skid steer bucket allows operators to handle materials like soil, debris, gravel, and snow efficiently. They can even clear land for construction, road-building, or farming purposes.

Are Skid Steer Buckets Universal?

Many modern skid steer loaders are designed with a universal mounting system that makes swapping between buckets convenient. This system works across a wide range of models and brands, making buckets extremely versatile. However, older skid steer models or more specialized machinery may not be compatible with this universal design.

For example, while a new skid steer model offers attachment flexibility, a larger model can handle heavier and more robust buckets for bigger, heavy-duty tasks. A smaller machine may not be compatible with broader, heavier buckets for future projects. If you plan to work on large jobs, consider a large skid steer that meets the task’s demands.

Factors That Affect Bucket Compatibility and Performance

Explore the following factors to ensure your machine’s bucket compatibility and support overall productivity:

- Bucket weight: The bucket’s weight should be properly balanced with the skid steer’s weight and capacity. Handling heavy materials such as rocks or concrete requires a powerful machine to handle the added weight without straining performance and safety.

- Flow requirements: Skid steers have an auxiliary hydraulic system that provides hydraulic flow to power attachments like augers that drill holes or brush cutters that remove vegetation. Attachments must have the same flow range to operate effectively, or they might malfunction or deliver poor performance.

- Application: The types of jobs you intend to perform will determine the kind of bucket attachment you’ll need. Consider the scope of your projects, the weight of materials and tasks, such as digging, trenching, lifting, and hauling, to understand which buckets you might need.

- Lifting orientation: If the task involves a lot of lifting, consider whether you’ll be raising objects horizontally or vertically. Some bucket designs are better suited for lifting wide objects horizontally, while others perform better by lifting vertically.

Before choosing a bucket for your machine, always consult your manufacturer’s specifications to confirm its compatibility. It’s also important to check your skid steer’s weight and size requirements. This will help you understand your equipment’s task limits and whether it can handle heavier jobs.

The Right Skid Steer Bucket Size

The bucket size plays a critical role in the performance of your equipment, directly influencing productivity, safety, and overall efficiency. An ill-fitting bucket can impact the skid steer’s maneuverability, stability, and material handling capabilities. Selecting the appropriate bucket size helps ensure your skid steer works optimally, avoiding unnecessary operational strain and safety risks.

Explore these key considerations to ensure you choose the right bucket size:

- Bucket width compatibility: The bucket’s width should align with or be slightly narrower than your skid steer’s width. Options that are too large can hinder maneuverability, especially in tighter areas like narrow construction sites in the city. This makes it challenging to perform more precise tasks.

- Rated operating capacity (ROC): Larger buckets can handle more materials, enhancing productivity by reducing the number of trips needed for transporting materials. However, don’t exceed your machine’s ROC — this can cause mechanical strain, hinder efficiency, and potential safety issues.

- Bucket and material weight: The bucket and the material it carries affect the skid steer’s stability. This is especially apparent when it moves on uneven terrain while carrying heavy loads. For this reason, it’s crucial to ensure the bucket’s weight is suitable for the skid steer’s tipping load.

How Many Cubic Yards Can a Skid Steer Bucket Hold?

The exact number of cubic yards a skid steer bucket holds depends on the equipment’s specific model and size. Generally, buckets are available in small, medium, or large options.

For the most accurate estimate, check out the specifications for the skid steer model you’re working with. This will offer the most relevant capacity information for safe and efficient operation.

How Much Does a Skid Steer Bucket Weigh?

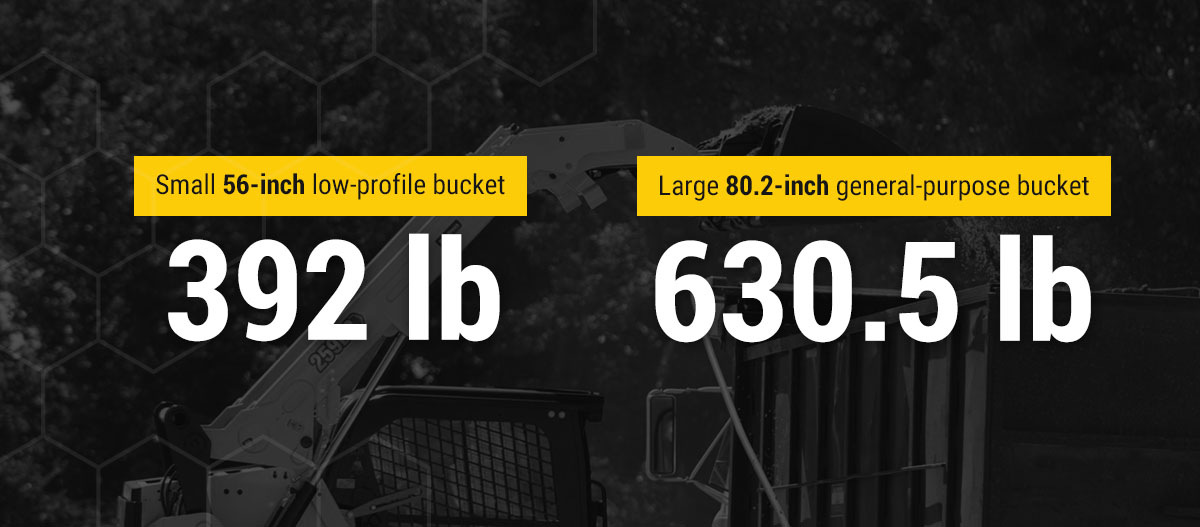

A skid steer bucket’s weight depends on its size. The larger the bucket, the heavier its weight.

For example, a small 56-inch low-profile bucket weighs 392 pounds. In contrast, a large 80.2-inch general-purpose bucket weighs 630.5 pounds. Likewise, heavier buckets have greater capacities. If you’re gearing up for heavier construction, landscaping, or mining jobs in the future, it’s worth investing in a medium to large-frame skid steer to attach midsized or large buckets.

Different Types of Skid Steer Buckets

Another way to determine the right bucket is to survey available attachment options in the market. Check out the bucket types for specific purposes below.

General Purpose Buckets

Ideal for a wide range of tasks, general-purpose buckets are highly versatile attachments used at many jobsites. They’re meant for light to moderate material handling, including digging, lifting, and moving materials such as soil, gravel, sand, and debris.

General-purpose buckets commonly have features such as smooth edges or bolt-on cutting edges. While both are ideal for handling materials, a bolt-on cutting edge skid steer bucket provides added protection, enhancing its durability and life span.

All-purpose buckets are available in various widths and are usually compatible with a range of skid steer models. They are commonly used for light construction, grading, farming applications, and landscaping. However, they may not be the best option for specialized jobs, such as handling rocks or sorting ground materials.

If you need attachments for more specific tasks, explore the following specialty buckets.

Rock Buckets

Designed to separate rocks and debris from soil, rock buckets help enhance construction, farming, and landscaping efficiency. Their durable, wide tines allow larger objects like stones and demolition waste to get caught in the bucket while soil sifts through. They easily remove rocks and debris for clearing and site preparation.

Skid steer skeleton rock buckets, in particular, have an open-back design that enables better visibility of the bucket’s cutting edge. This also helps operators see sharp or protruding debris, preventing potential tire issues. Rock buckets are also used for scrap handling applications and to clear land overgrowth.

Bolt-On Bucket Teeth

Also called a tooth bar or tooth bucket, bolt-on skid steer bucket teeth significantly enhance digging performance. They’re designed to cut through rocky soil, break up solid materials, and excavate roots in challenging conditions. In addition to more efficient digging, the bolt-on feature enables operators to remove the teeth for replacement or repairs conveniently.

Compared to permanent weld-on teeth, bolt-on bucket teeth provide quick replacement after an excavating job. If the next task immediately involves site-clearing, such as snow removal or back-dragging, there’s no need to use different equipment.

Low-Profile Buckets

A low-profile bucket is ideal if you need an attachment that improves visibility and ease of movement. It’s excellent for tight spaces or areas that require precise earth-moving tasks.

Designed with a lower back and sidewall, it lets the operator see the bucket’s edge, which is important for properly grading and leveling the ground. Consider this option from our skid steer bucket guide if you require enhanced operator visibility.

The low-profile bucket’s flat bottom contributes to better grading and material handling. Its heavy-duty construction also ensures durability for tough tasks. In addition, this bucket is equipped with optimized dump angles for faster unloading, helping save valuable time on the job.

Grapple Buckets

Equipped with hydraulic claws, a heavy-duty grapple bucket provides a secure grip on irregular and bulky materials. It’s well-suited for handling logs, boulders, and large debris. Grapple buckets enable operators to grab and move objects more precisely than a standard bucket without claws. They enhance your productivity with a firm hold on materials during transport.

With a powerful hydraulic mechanism, operators can securely handle unwieldy materials of various shapes and sizes. This helps reduce the risk of accidents or materials falling on the ground, improving safety and operational efficiency.

High-Capacity Buckets

High-capacity buckets are built to move large volumes of material with ease. Crafted with deeper buckets and a more durable design, they can withstand heavy loads without straining performance. They also come with extended bottoms that offer improved visibility, enabling the operator to better see the bucket’s cutting edge.

High-capacity buckets are fitted with a bar across the bottom rear for added reinforcement. This protects the bucket from wear and improves its strength. They are ideal for handling large jobs such as extensive earth-moving tasks. Consider high-capacity buckets from our skid steer bucket guide when you need to carry heavy loads in the least amount of time.

Snow and Light Material Buckets

Designed to handle large volumes of low-density materials, snow and light material buckets are well-suited for snow removal and material transport. This includes low-density materials like sawdust, mulch, and wood bark. With their deep structure, high back, and sides, they efficiently carry loose materials while maximizing capacity for quicker job completion.

Snow and light material buckets are not made for digging. They are lighter than rock buckets and prioritize increased material volume over strength. For optimal performance, use them for their intended purpose and leave the heavy digging to more specialized attachments like tooth buckets.

How to Change a Bucket on a Skid Steer

The steps to replace a skid steer bucket depend on the model and whether it has a manual or quick coupler. To be sure, it’s best to follow your manufacturer’s instructions or review your equipment manual for specific steps in changing your bucket model.

The following are general steps you can refer to in changing your skid steer bucket:

- Position the new bucket on the ground directly in front of the skid steer.

- Lower the coupler and slowly drive the machine towards the bucket.

- Lift and tilt the coupler back until it aligns with the bucket.

- If your skid steer has a manual coupler, exit the cab and securely lock the pins. If your skid steer has a quick coupler, engage the bucket by pressing and holding the switch from the cab.

- Angle the bucket down and push it back to check if it’s attached securely.

- Slightly lift the bucket and visually check if the pins are properly engaged.

- Finally, connect your hydraulic hoses by following the instructions in the manufacturer’s manual.

Securing the Right Skid Steer Loader Bucket

When securing a skid steer loader bucket, you have three primary options:

- Buy new: Consider investing in a new bucket if you regularly utilize it for common project tasks. New options will give you long-term use and have the latest features.

- Buy used: If you’re looking to save costs but still require a skid steer loader bucket for frequent use, buying used is a great way to get the equipment you need at a lower price.

- Rent: For short-term project needs, renting a bucket allows you to fill gaps in your fleet and get the job done. You can also leverage rental attachments to determine which model is right to invest in for your business.

Explore our Selection of Cat® Skid Steer Buckets at Thompson Tractor

Searching for the right heavy-duty skid steer bucket? Whether it’s for small or large construction jobs, public infrastructure projects, industrial mining, or agricultural landscaping, Thompson Tractor offers high-quality skid steer buckets for your needs. Browse our online catalog of skid steer buckets to find what you’re looking for. We also provide a wide inventory of sales and rental attachments for your heavy equipment.

Thompson Tractor has been in business since 1957 and is the premier dealer of full-line Cat equipment sales, parts, and services to clients throughout northwest Florida and Alabama. We are your one-stop shop for all your heavy equipment needs, with friendly and knowledgeable staff ready to assist you.

Reach out to us online or visit us at one of our locations to learn more about our available skid steer buckets. We look forward to serving you.